In industries where equipment faces consistent abrasion and impact, wear-resistant steel is not just an option—it’s a necessity. Working with Authorised Distributors of Wear Plates ensures that you receive high-quality, certified materials built to handle the harshest conditions. These distributors serve as reliable links between manufacturers and end users, offering access to products that meet global standards.

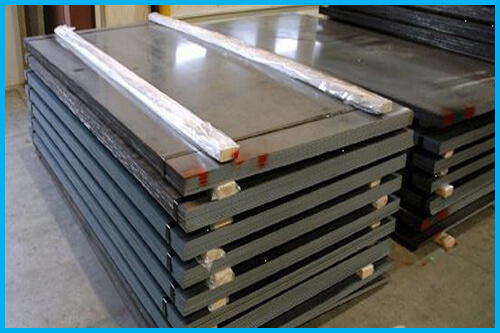

Wear plates, such as the widely used AR 400, are engineered to provide exceptional resistance in heavy-duty environments. With a nominal hardness of 400 HBW (Brinell Hardness), AR 400 is a go-to material for liners, buckets, hoppers, and other high-wear surfaces. These plates conform to international quality standards like ASTM A514, EN 10051, and DIN EN 10163, ensuring consistent performance and durability.

Choosing Authorised Distributors means working with entities that have been verified by original Wear Plates Manufacturers. They provide traceable inventory, mill test certifications, and compliance documents, so you can be confident in the material’s integrity. Their role is critical in preventing the circulation of substandard or copyright materials in the market.

Many of these distributors are also experienced Wear Plates Importers, bringing in globally recognized brands and maintaining local stock to fulfill demand quickly. They often support additional services such as custom cutting, forming, and delivery logistics to help streamline your procurement and fabrication processes.

With distributors operating under authorization, you not only receive genuine wear plates but also expert guidance on the right grade and thickness for your specific application. This helps optimize performance, reduce downtime, and extend the life of your equipment.

In summary, partnering with Authorised Distributors of Wear Plates is the smart choice for anyone seeking certified, abrasion-resistant steel backed by technical support and trusted service. It's your best route to quality, reliability, and long-term value.